Sluicing

Sluices use water to wash ore or alluvium down a series of angled platforms. As water washes sediment down a sluice, gold particles sink and are captured by material covering the bottom of the sluice, often carpets. Sluices are usually inclined at 5 to 15 degree angle. As moving water travels down a sluice, it generates greater force and keeps gold particles from sinking easily. For this reason most gold is captured at the beginning of the sluice. Carpets or other capturing devices on the bottom of sluices can be removed and washed in a bucket to remove the captured dense material.

Sluice design can lead to higher gold recovery if the force of the water traveling through the sluice is decreased. A series of rifles can help break the flow to improve recovery. A zig zag sluice also achieves this by creating a drop between the first and second platform that disrupts the velocity of the water as it travels down the sluice.

A simpler alternative to the zig zag sluice is a combination of two sluice surfaces. The first is tilted at a steeper angle then the second, decreasing the velocity of the water as it hits the second sluice, increasing gold recovery.

Sluices can be relatively expensive or affordable depending on the complexity of their design. Simple sluices can be a single angled platform a few feet in length and others can be very elaborate.

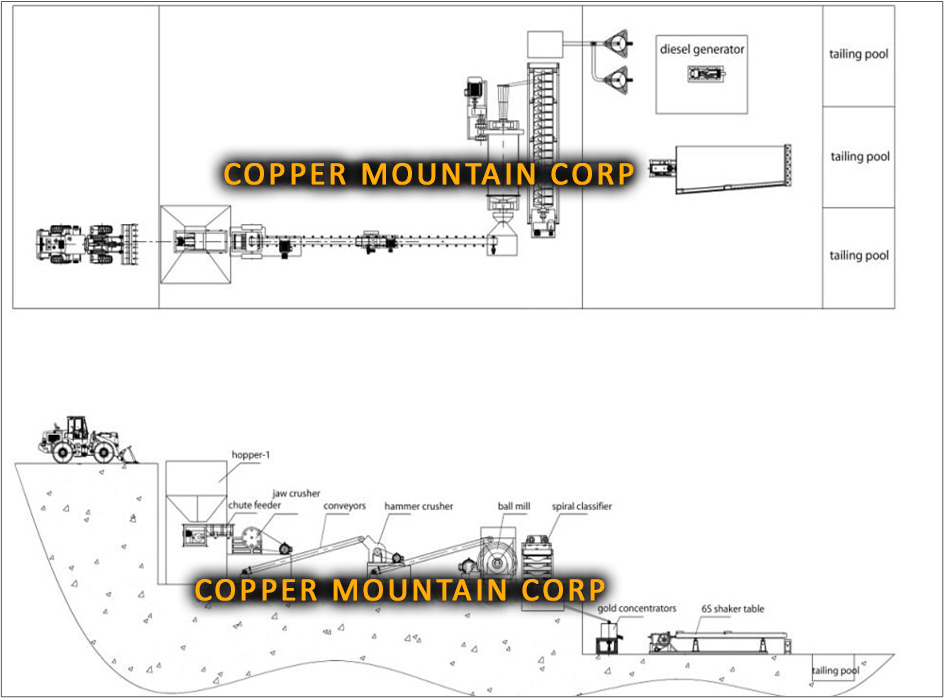

Having an available and consistent water supply is necessary to have a functioning sluice operation. This can be done with piping, drums, buckets, or natural flowing water bodies. A constant flow will be better than a bucket-driven flow.

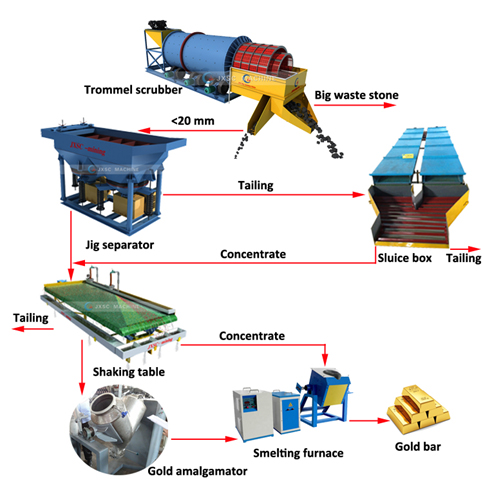

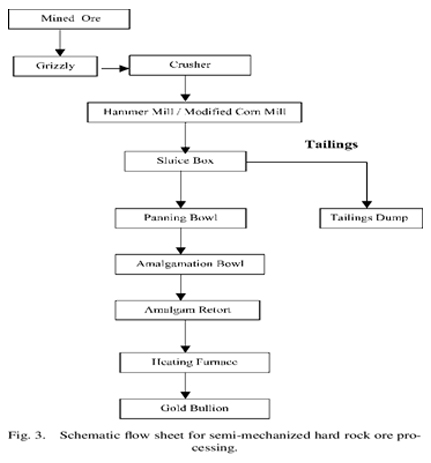

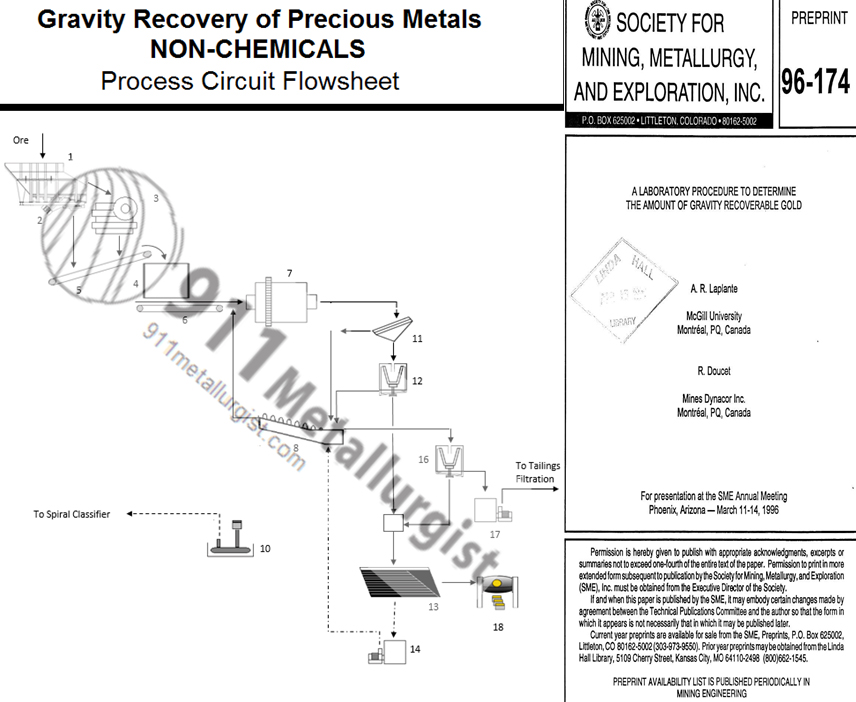

Sluices are good at concentrating large amounts of ore and sediment in a relatively short time but often do not yield concentrates with high amounts of gold. The resulting concentrate must usually undergo further methods of concentration, such as panning.